Activities

Working in accordance to Technical and Juridical Standards and applying National, European and International Codes and Specifications, our service concerns of non-destructive examinations, local heat treatment of welding, inspectorial activities such as real expediting, plant’s inspection and executive supervision of welding.

NONDESTRUCTIVE EXAMINATIONS - HEAT TREATMENT - INSPECTIONS OF LINES AND PLANTS

X-ray and gamma ray radiographs

Ultrasonic testing, traditional methods and thickness measurement

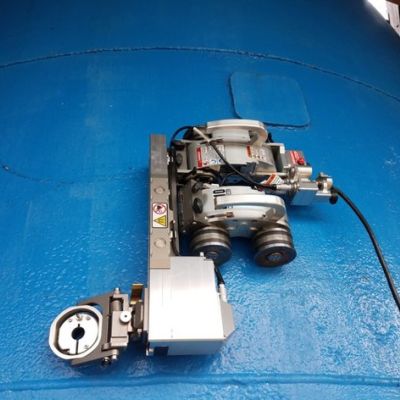

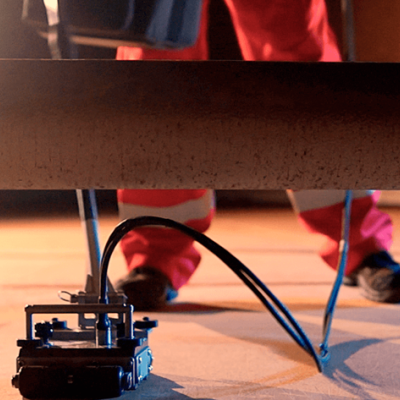

Robotic thickness control

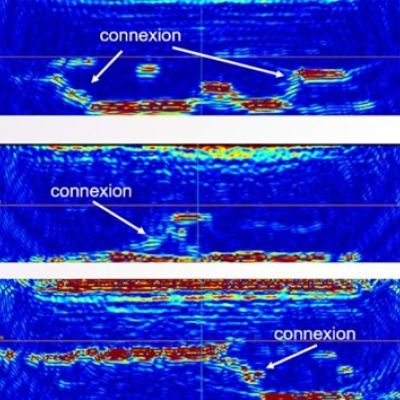

TOFD, C-B scan, Phased Array ultrasonics - AUBT

*

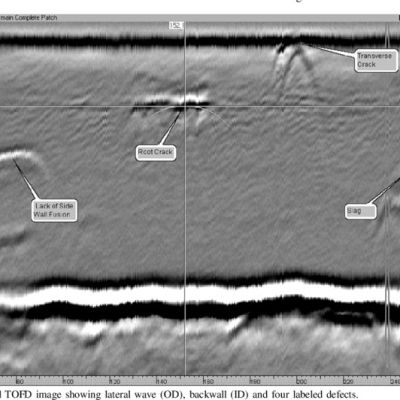

TOFD (Time Of Flight Diffraction) ULTRASONIC CONTROLS

*

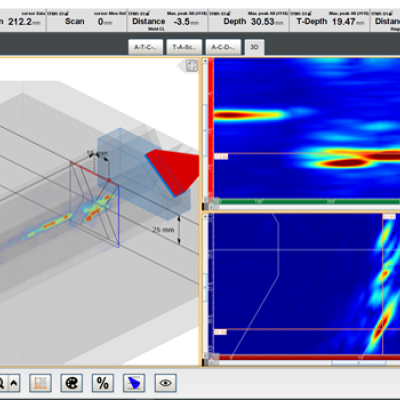

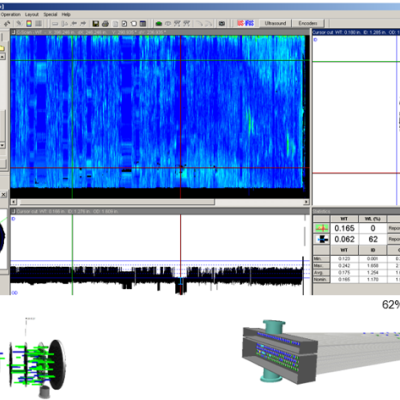

ULTRASONIC TESTS TFM (Total Focusing Method)

*

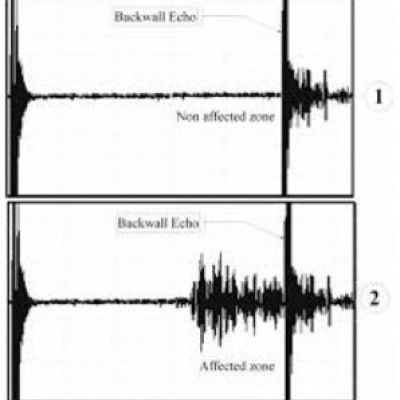

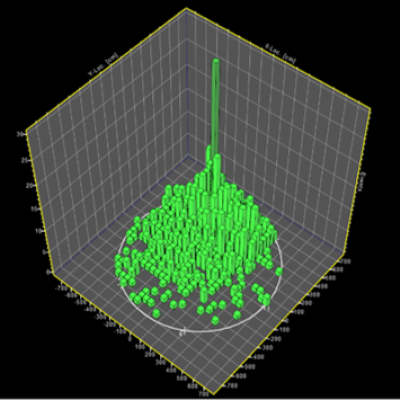

AUBT ULTRASONIC CONTROLS (Advanced Ultrasonics Backscatter Tecnique)

*

ULTRASONIC CONTROLS H2S WET

*

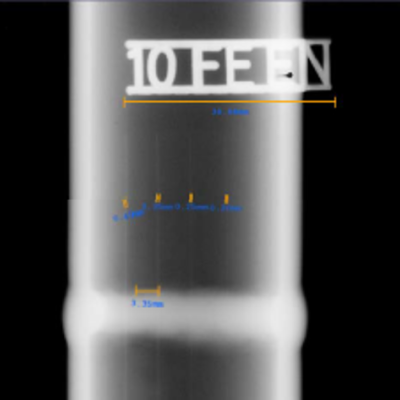

ULTRASOUND CHECKS CORROSION MAPPING (T-scan)

*

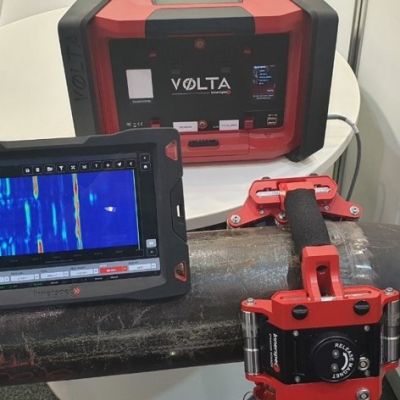

ULTRASONIC CHECKS WITH ANYSCAN TYPE MAGNETIC SCANNERS

*

IRIS (Internal Rotary Inspection System) ULTRASONIC CHECKS

*

ULTRASONIC WAVE CHECKS LRUT GUIDED WAVE (Long Range Ultrasonic Testing)

*

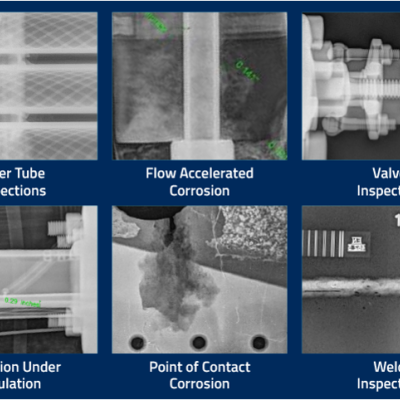

DIGITAL RADIOGRAPHIC CONTROLS

*

GAMMASCANNING TRUSCAN CONTROLS

*

DIGITALIZATION OF X-RAY FILMS

*

MFL CONTROLS WITH FLOORMAP X

*

MFL CONTROLS WITH HANDSCAN

*

MFL CONTROLS WITH PIPESCAN

*

PEC CONTROLS (Pulsed Eddy Current)

*

TECA CONTROLS (Tangential Eddy Current Array)

*

EMAT (Electromagnetic Acoustic Transducer) CONTROLS

*

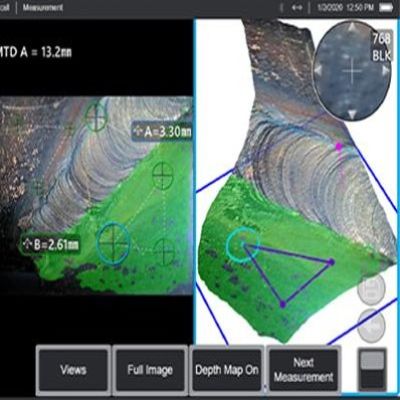

3D VIDEOENDOSCOPIC CONTROLS

*

Sealing checks with vacuum box

FLOW METER CONTROLS

*

MULTIFUNCTIONAL DEMAGNETIZATION SYSTEM

*

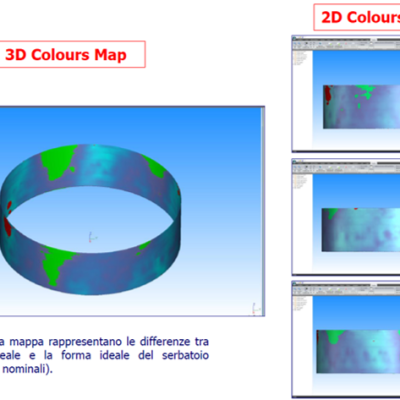

LASER SCANNER CONTROLS

*

QSR (Quantitative Short Range) CONTROLS UNDER THE MEDIA

*

MAGNETOINDUCTIVE CONTROLS ON METALLIC ROPES

*

MRUT CONTROLS (MEDIUM RANGE ULTRASONIC TESTING)

*

ULTRASONIC PHASED ARRAY CHECKS validated for small thicknesses and small diameters

*

UT-semiautomatic (SAUT) and automatic, IRIS, P-SCAN and T-SCAN monitoring corrosion

*

APR - Acoustic Pulse Reflectometry

*

Magnetic Particle

Liquid penetrant

Induced currents traditional methods

Magnetic flux leakage

*

CONTROLS WITH ACOUSTIC EMISSIONS

*

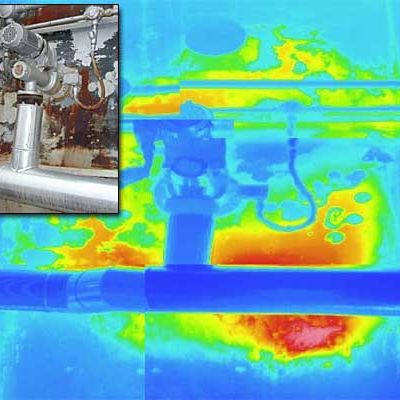

INFRARED THERMOGRAPHY

*

Fiberscope and visual testing

High definition 3D video endoscopy

*

Inspection with high definition CA-zoom video camera

*

TIGHTNESS CHECKS WITH HELIUM TEST

*

Metallographic control and measure of ferrite

P.M.I. CHECKS WITH CARBON

INDUCTION AND RESISTANCE HEAT TREATMENTS

HEAT TREATMENTS IN GAS OVEN

Inspection of lines and plants

For the execution of non-destructive examinations of welding, plant’s parts or components, we use either the most traditional methods (industrial radiography, ultrasonic inspection, thickness ultrasonic measurement, magnetic particle examination, liquid penetrant examination, eddy currents, etc) or those more innovative like computed radiography, ultrasonic C-B scan, T-scan and AUBT, UT thickness with robotic systems and probes EMAT (Electro Magnetic Acoustic Trasducer), TOFD/Phased Array, automatic (pipe-wizard type), semi-automatic SAUT and with guided waves, PEC (Pulsed Eddy Current), tecnica TECA (tangential eddy current array) with probes SHARCK, acoustic emission examination, material’s analysis or PMI, thermal infra-red inspection, video-endoscopy and so on depending on the needs and demands of clients.

The constant technological innovation of our methods and equipment allows us to offer our Customers the most evolved application of every single method requested to our Society.

Solution.

"The most appropriate solutions and the interventions to be carried out are studied and put into practice with the utmost professionalism, to offer a serious and timely Service that is always constantly updated"

/ Nondestructive examinations

/ Heat treatment

/ Inspections of lines and plants

Office

-

Zona Industriale Porto Salvo

89900 Vibo Valentia (VV)

Privacy

Contact

-

(+39) 0963 567678

-

This email address is being protected from spambots. You need JavaScript enabled to view it.

This email address is being protected from spambots. You need JavaScript enabled to view it. -

VAT IT01224630796